Mobile Robot Platformen (MRP)

Mobile use of KUKA QUANTEC & IONTEC robots – economical, flexible, scalable

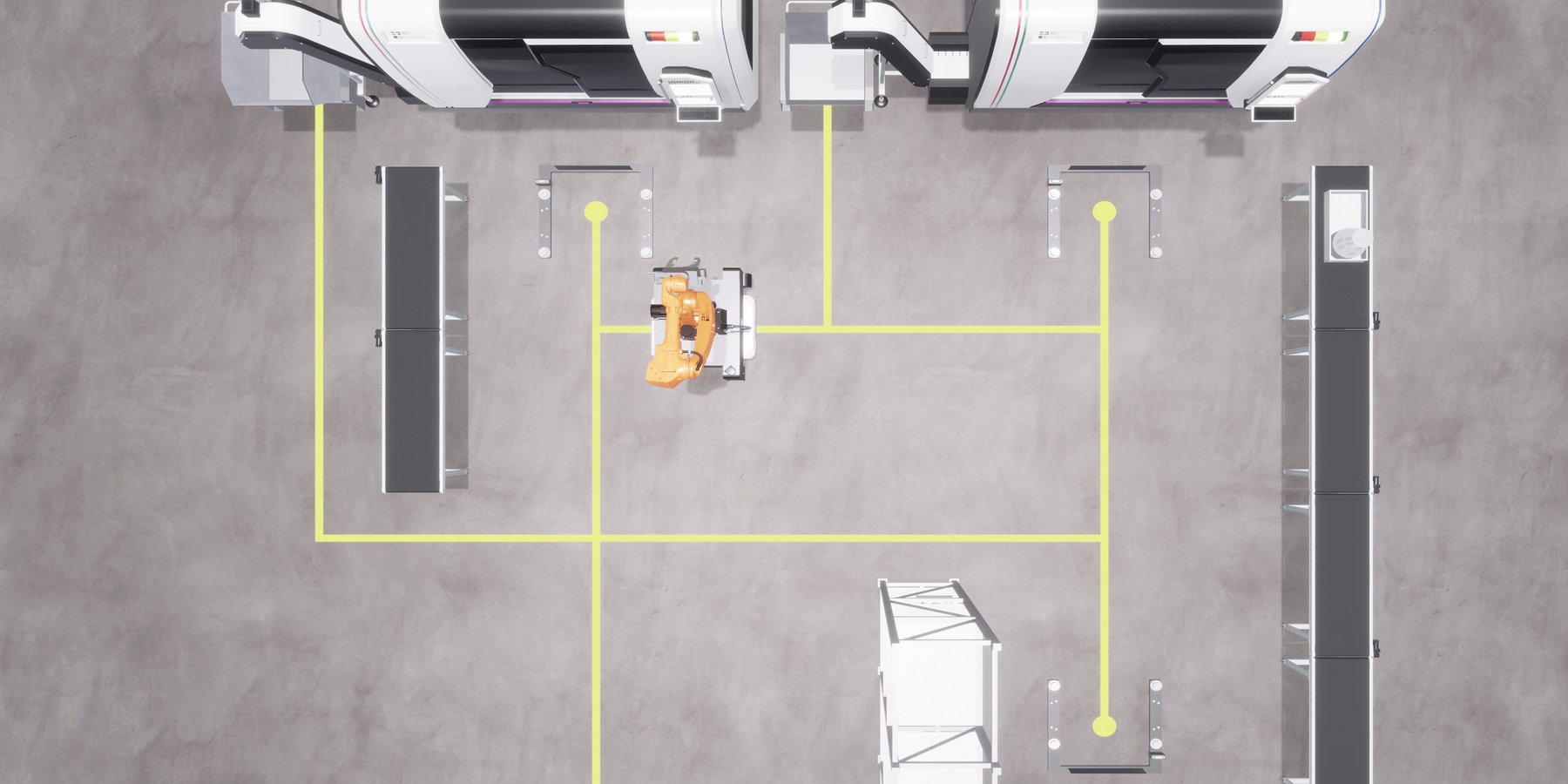

Architecture of the Mobile Robot Platforms

The MRP systems from BEC Robotics combine a base that can be transported by AGVs with industrial robots from the KUKA IONTEC and QUANTEC series.

The MRP base is equipped with all the components required for autonomous operation. These include a PLC, a robot controller (KRC5), safety sensors, a module for communication with machines and systems, an integrated power supply, and a compressed air storage tank for the docking system.

Flexible deployment, exact positioning, rapid startup

MRP transported by standard AGVs – operational in seconds via smart docking

Efficient transport with AGVs

The MRP systems are moved between the operating stations using standard AGVs, such as the KUKA KMP1500. The vehicles drive under the MRP base, lift it up, and move it autonomously to the desired station. The AGVs are not exclusively intended for transporting the robot platform: after delivering the MRP to the docking station, they are immediately available again for other logistical tasks. This increases the overall utilization of the vehicle fleet and boosts cost-effectiveness.

Precise docking for maximum process reliability

At the respective location, the MRP automatically connects to a permanently installed docking station. This station provides mechanical fixation as well as power, compressed air, and communication connections. All necessary media are usually already available on site, as they are typically required for the operation of the machine or system. This reduces installation costs and enables easy retrofitting of existing production areas.

Dock and Produce in 15 seconds

Thanks to its smart system architecture and custom-fit docking design, the MRP unit is fully operational within just 15 seconds of docking. All the MRP has to do is connect to the docking station. Camera-based referencing or calibration of the robot is not necessary. As soon as the safety area is clear, the robot can enter the process directly – with the precision of a stationary robot, but with complete location independence.

Key MRP advantages

(1) Proven KUKA technology

(2) Compact, space-saving design

(3) Power and compressed air via docking stations

(4) Quick start-up of the robot on site

(5) Additional docking stations can be easily integrated

(6) Cost-effective automation solution

Automation with standard mobile robotics

While fully integrated systems such as the KUKA KMR iisy or KMR Cybertech impress with their compact design and battery operation for payloads under 25 kg, comparable concepts reach their functional limits in large-scale robotics such as the KMR Quantec. Power is supplied by large-format batteries and converters housed in a massive carrier platform with a footprint of over 4 m². The high total weight of the systems ensures the necessary stability during robot operation, but significantly restricts the mobility of the mobile unit. In addition, the positioning accuracy of the platform, at ±5 mm, is not sufficient to integrate the robot precisely into the process without camera-based correction.

The MRP concept from BEC Robotics solves these challenges by consistently decoupling the robot, transport, and power supply.

The robot is operated stationary on a base that can be transported by standard AGVs, which is mechanically fixed on site via a precise docking station and supplied with power, compressed air, and data. The AGVs are exclusively responsible for transporting the robot platforms and are immediately available again for other value-adding tasks after handover – economical, scalable, and efficient.

Safe automation

BEC Robotics' MRP systems feature a fully integrated safety concept. The vehicle's safety scanners monitor the environment during transport. During this phase, the robot is in a safe parking position. Only after precise docking at the station does the system activate the robot-assisted application – provided that the monitored safety zones report clearance. The safety architecture is adapted to each specific project on the basis of a risk assessment, thus enabling safe and efficient operation.

Areas of application

- Operation of multiple machines by one robot

- Machine interlinking with minimal structural effort

- Redistribution of AGV loads (buffer storage)

- Palletizing and depalletizing with high unit weights

- Handling tasks such as conveyor belt removal and container filling

- Easy retrofitting of existing systems

Do our Mobile Robot Platforms meet your requirements or fit your project idea?

Then contact us - we look forward to hearing from you!

Contact

Overview of mobile robotics solutions from BEC Robotics

Scalable mobile robot solutions – flexibly adaptable up to a payload of 300 kg

BEC Robotics develops powerful mobile manipulators and autonomous mobile robots (AMRs) for industrial applications with payloads of up to 300 kg. Our modular systems combine proven KUKA robotics with robust driverless transport systems (AGVs), enabling flexible use in industrial automation, intralogistics, and sensitive areas such as clean rooms. Thanks to their modular architecture, our systems can be tailored precisely to customer-specific requirements, for example in terms of load capacity, reach, gripper technology, power supply (stationary or battery-powered), and operating environment. This results in scalable, economically efficient automation solutions that are both technically and economically impressive.