Industrial robot applications

Streamline operations with BEC Robotics' industrial robotics solutions

Multi-tool end effectors and combi grippers

Our advanced multi-tool end effectors increase robot versatility and efficiency in a variety of applications. Designed to eliminate time-consuming tool changes, our innovative gripper systems increase process speed and productivity. Seamlessly perform multiple tasks with our robotic solutions for greater production flexibility and operational efficiency.

High-performance linear rails for medium to heavy payload robots

The BEC linear rails are designed to support robots with medium to heavy payloads, including powerful models such as the FANUC M-2000iA/2300 and the KUKA Titan. For mid-size robots, a ceiling-mounted version is available for payloads up to 300 kg. Designed to deliver precision and accuracy in demanding environments, they are scalable and modular for easy adaptation to your production needs. With high-speed performance and rugged durability, they handle time-critical tasks while ensuring long-term reliability.Safety is a priority with advanced features such as collision detection. Customize our rails to meet your operational needs and enhance your production line with BEC Robotics solutions.

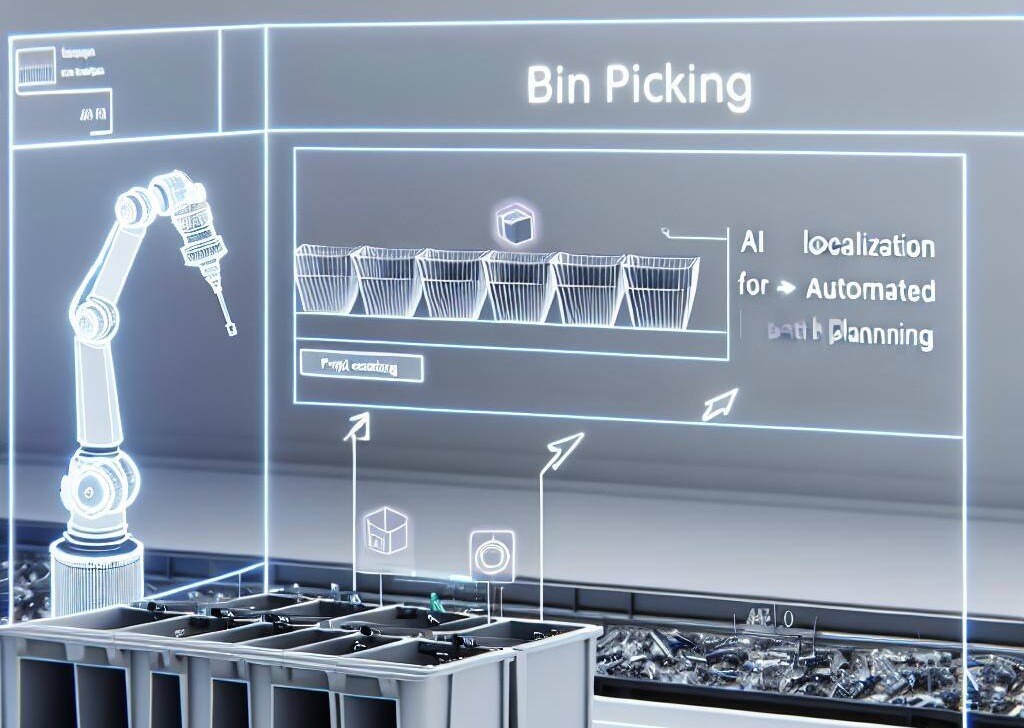

AI-driven bin picking and path planning solutions

BEC uses state-of-the-art camera and AI technologies to transform bin picking, part localization, identification, and automated robot path planning. By partnering with leading providers of AI and camera technology, we deliver precision-engineered solutions for diverse industrial applications. Our advanced systems integrate high-resolution 2D and 3D cameras with sophisticated AI algorithms to automate processes. Real-time camera data is processed by AI to accurately identify and locate parts regardless of shape, size, or surface texture.This enables precise gripping and collision-free path planning for robots that can easily handle complex scenarios such as overlapping items and variable lighting conditions. Our strategic partnerships with leading technology providers ensure that our solutions are not only highly efficient, but also adaptable to different industrial environments.

Leading solutions for robotic automation

For 20 years, BEC Robotics has been providing state-of-the-art robotic solutions for automating production processes in a variety of areas, including clean room environments, general manufacturing and mobile automation. We support both brownfield and greenfield projects. Our experience covers the successful automation of manufacturing processes for small parts up to over 1 ton in weight. We are able to meet a wide range of automation requirements and do not shy away from special requirements. We focus on seamless integration into the existing software environment and work with state-of-the-art safety systems to ensure safe and efficient collaboration between humans and robots. Our customized automation solutions improve existing processes and offer significant benefits such as increased productivity and lower operating costs.

Advanced robotics solutions for production

BEC Robotics is a leading provider of robotic solutions for advanced manufacturing. Our innovative technology improves manufacturing efficiency and precision, setting new standards in the industry. A prime example of our impact is the livMatS Biomimetic Shell at the FIT Freiburg Center for Interactive Materials. This groundbreaking research facility showcases our state-of-the-art robotic manufacturing cells integrated with computational design and automated construction processes. The facility's highly resource-efficient timber shell reduces environmental impact by 50% compared to traditional methods. Discover how BEC Robotics can revolutionize your manufacturing processes and increase your sustainability goals.