Industry

Automation with robotics and mobility

- Industry

- Products & Services

Mobility and production efficiency

Improve your operational capabilities with BEC Robotics' advanced systems for Industry 4.0. With our extensive experience and technical expertise, we offer seamless digital integration that optimizes material handling and production processes.

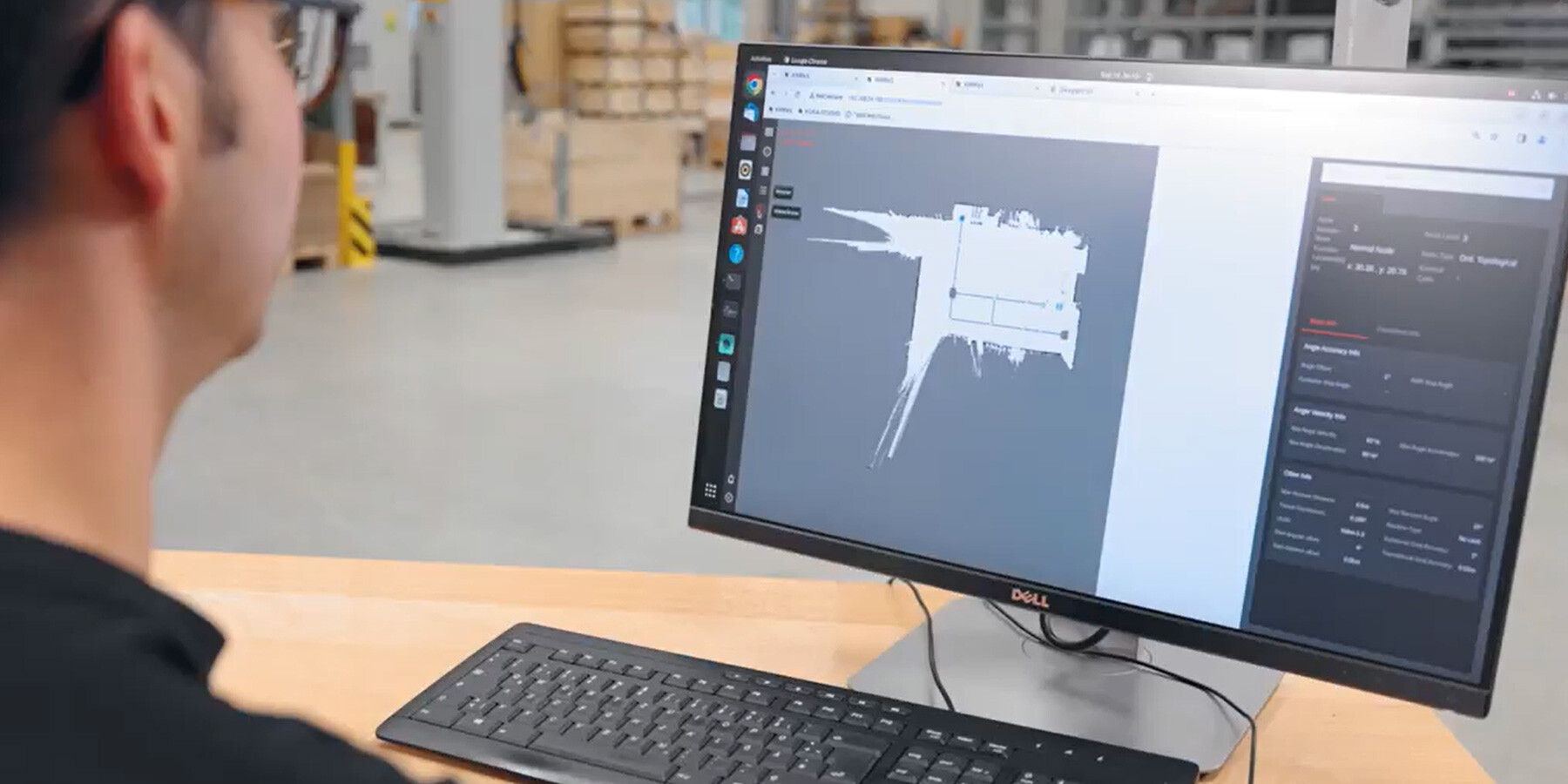

For advanced Fab Automation, we partner with KUKA to deliver innovative cleanroom robots, collaborative robots (cobots) and mobile platforms designed specifically for semiconductor manufacturing, where stringent cleanliness and safety standards must be met. Our mobile robot and cobot portfolio includes KUKA's KMR CYBERTECH, KMR iiwa and KMR iisy nano mobile manipulators, fully integrated on mobile platforms to provide customized solutions for various industrial automation needs. Our Autonomous Mobile Robots (AMRs), Automated Guided Vehicles (AGVs) and AGV forklifts handle a range of loads, from small pallets to heavy components, with platforms that can be deployed within hours and are designed to work safely alongside human workers in a variety of environments. We specialize in optimizing manufacturing processes with custom industrial robotics applications, including factory automation, advanced robotic grippers and sophisticated AI vision systems. For intralogistics, we offer both standard and custom software solutions that improve system integration and streamline operational efficiency.

Optimize Your Operations with BEC Robotics

For projects requiring AGVs or AMRs, BEC Robotics provides cost-effective, efficient, and flexible solutions to improve operational efficiency. Contact us to explore how our advanced robotics technology can elevate your business.

Get started now!

Transform your intralogistics with BEC Robotics

Do you have a project that requires AGVs or AMRs? Partner with BEC Robotics for cost-effective solutions that improve efficiency, accuracy and flexibility. You are just one click away!

Explore our full range of solutions for industrial automation

Mobile Robots Reimagined: The MRP Concept for Payloads up to 300 kg

Automatica 2025